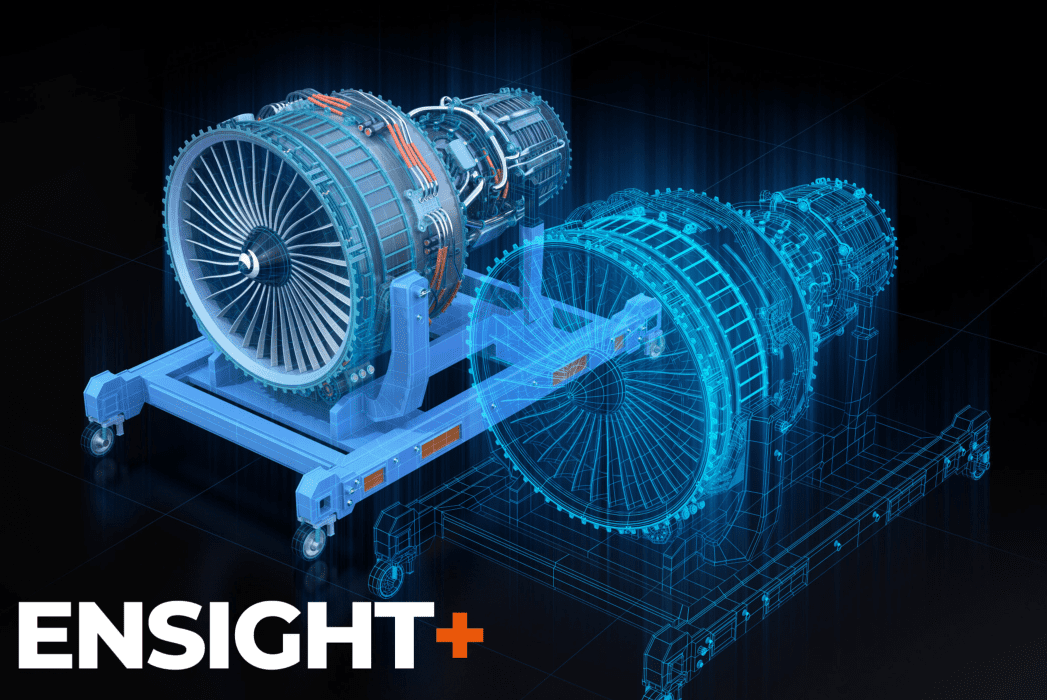

Digital twin technology has gained steady attention from utilities in the past five years. The term “digital twin” has existed for over a decade, used mainly in highly technical engineering projects. So, what is a digital twin? The term applies to a variety of different simulation technologies, but “digital twins” primarily describes AI models of existing structures. Consider digital copies of DVDs or music albums; they retain all the information and characteristics of the physical object, but exist in a hard drive or on the cloud. Business use cases for digital twins are a newer arena. However, it makes sense for forward-thinking utility heads to utilize them where appropriate. Nearly half of utility executives are now using digital twins to sharpen their operational efficiency and increase the value of predictive analytics data. Juniper Research shows the digital twins market will grow by up to 35 percent annually until 2023.

Why Digital Twins?

Using digital twins, companies can run simulations demonstrating how their assets behave and respond in any scenarios imaginable. This gives engineers and operations heads valuable information about the performance, maintenance, and longevity of their assets. In some cases, digital twins are even more sophisticated. At this level, they enable utility firms to run large-scale, simulated replicas for their entire operation. An example of this would be using the technology to see what happens if the power generated by distributed energy resources suddenly tripled. These scenarios allow utility companies to glimpse into any number of hypothetical futures. Digital twins are a vital resource in an industry poised to utterly transform over the next decade. Here, we explore how utilities can harness digital twins to make smarter, more informed operational decisions.

Using digital twins, companies can run simulations demonstrating how their assets behave and respond in any scenarios imaginable.

Take Predictive Analytics to the Next Level

Predictive analytics (PA) has fast become a powerful tool in the utility industry. PA provides historical information, performance indicators, and various data points related to specific components and parts. Company heads can use this to understand their total assets on a deeper level. PA can gauge the real-time condition of this infrastructure, providing a clear picture of assets’ health.

PA provides historical information, performance indicators, and various data points related to specific components and parts. Company heads can use this to understand their total assets on a deeper level.

Predictive Analytics and Digital Twins

Creating digital twins is an extension and evolution of PA. Building on all the data that predictive analytics use, digital twins enables utilities to create digital replicas of their equipment and assets. It can then put the replicas in various scenarios that test resilience and failure rates over time. Digital twins are, in a way, the logical endpoint of predictive analytics.

Digital twins allow utilities to test equipment without exposing it to the elements and other damaging conditions. Putting digital twins under unique or extreme conditions can yield novel data that are unlikely to arise in normal circumstances. In this way, DT gives operational teams the chance to learn more about breakdowns, failure rates, and subsequent downtime. The technology can also shed critical light on rare but potentially catastrophic scenarios, strengthening companies’ disaster protocols, and minimizing future fallout.

Test Maintenance Scenarios Without Deployment

Digital twins are more than just repositories for massive amounts of potential data, though. They’re also interactive and “hands-on” in a way that many of the utility industry’s latest technologies are not. Technicians and engineers can use the digital replicas of field assets to experiment with different maintenance situations. For example, let’s say a field team wants to learn more about the best practices for a specific gas pipeline repair. Techs can actually reproduce these scenarios in an office, warehouse, or plant, and then troubleshoot through how to resolve them. This is far more effective and less expensive than waiting for the infrastructure to break down to create a learning opportunity.

Digital Twins Have Positive Effects at Every Organization Level

What do predictive maintenance, behavioral analytics, and distribution automation have in common? Tech upgrades like these aren’t usually felt at the level of the field service engineer (FSE). Many field service chiefs will tell you, though, that their FSEs are their most important assets. They possess the proficiency to maintain equipment and resolve complicated, time-sensitive service requests. They keep operations running smoothly by virtue of their intimate knowledge of utility infrastructure. Digital twins help FSEs build on those critical skillsets, instead of replacing them. Technicians and engineers can grapple with the digital counterparts to any pump, pipe, transformer, or valve found in the field. With this extra practice, they can grow their expertise much faster.

Employing digital twins in this way is also an excellent method for bringing up younger technicians. It can help to compensate for institutional knowledge lost when older techs start retiring in the coming years. During this period, utility companies will be losing irreplaceable baby boomers who’ve been around their infrastructure for decades. With digital twins, this knowledge can be saved and it will be much easier to cultivate a rising generation of field professionals.

Final Thoughts on Predictive Analysis with Digital Twins

Digital twins enable utility pros to see into the future of their assets, observing how they hold up under extreme temperatures, violent storms, and many years of ongoing use. Field service management (FSM) software equips companies to maximize the present. The latest, most cutting-edge FSM platforms feature several of the most important emerging technologies in the industry, including analytics reporting, cloud computing, and dynamic geo-mapping from multiple devices. These platforms guide field service managers toward sharper, more informed operational decisions on a daily basis, and are able to give organizations a boost no matter their level of technological immersion.

Here’s another way to look at it: field service management software such as EnSight Plus provides the same level of deep data and actionable insights into operational efficiency that digital twins yield for field infrastructure.